SICK Sensors

SICK is one of the world’s leading producers of sensors and sensor solutions for industrial applications. SICK is a technology and market leader in Factory and Logistics Automation as well as Process Automation. As a technology and market leader, SICK provides sensor intelligence and application solutions that create the perfect basis for controlling processes securely and efficiently, protecting individuals from accidents, and preventing damage to the environment. Long Distributors Ltd. is an Irish distributor for SICK sensor products across all industries.

SICK Distributors Ireland

Here at Long Distributors, we provide technical support and cost-effective solutions for SICK sensors in Ireland.

Our product range consists of established brand leaders, as well as solutions from innovative new companies, and we specialise in sourcing non-standard products, including variations on standard products and alternatives to obsolete items.

We will always be on hand to help you to find comprehensive solutions to unconventional problems.

SICK Product Enquiry

SICK Products

SICK Proximity Sensors

SICKs sensors are perfectly suited to industrial applications and requirements. SICKs inductive, capacitive and magnetic proximity sensors offer a long service life, extreme ruggedness and the utmost precision. SICK intelligently and reliably solves industry-specific and individual automation tasks.

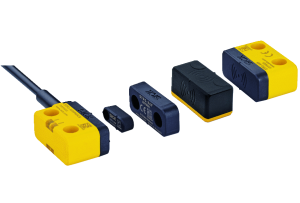

SICK Safety Switches

Safety switches are indispensable in any application where safety is required for people and machinery. They are used for protecting movable physical guards, determining the position of dangerous movements, and the safety stop function. The portfolio is divided into electro-mechanical and non-contact safety switches, safety locking devices, and safety command devices.

Automation Light Grids

Two-dimensional inspection or counting tasks are important in automation. SICK’s automation light grids can be used in a number of these solutions, such as detecting and counting irregularly shaped objects, people and vehicles, and checking for presence and pallet overhang detection. The tasks are so versatile that one light grid cannot fulfil the requirements of every application. Light grids from SICK offer multiple ranges, heights, sizes, orientations, and resolutions which simplify integration through high flexibility and performance.

Encoders

Paths, position, angle – an encoder is the ideal solution when it comes to precise position detection in industrial automation. The same applies to measuring revolutions and rpm as well as speed and acceleration. High-resolution optical encoders and extremely rugged magnetic encoders complement one another perfectly and permit exact measurements in all kinds of applications. Rotary encoders are available as incremental and absolute encoders. Wire draw encoders and linear encoders with a measuring element are available in linear measuring technology.

Safety Systems & Solutions

In addition to reliable safety components, SICK also offers solution-oriented services and certified, ready-to-install safety systems in order to provide protection for machines and plants. When implementing their projects, plant operators can rely on experienced safety experts from SICK and receive comprehensive, economical safety solutions from a single source.

Detection & Ranging Solutions

The LiDAR (Light Detection and Ranging) laser measurement technology provides solutions for a wide range of applications. The two or more dimension contour data recorded can be processed both internally and externally. The technology is ideal for indoor and outdoor applications, like anti-collision in ports, detection in building automation, classification in traffic, or position evaluation in navigation.

Distance Sensors

SICK has a wide range of optic and ultrasonic solutions that measure from sub-microns to kilometres. They solve measuring, detecting and positioning applications using triangulation and time-of-flight modes. Sensors using triangulation are ideal for short-range, highly precise measurement. They can inspect miniature parts, thickness and shape, etc. Time-of-flight sensors work at longer distances, are not influenced by reflectivity or ambient light − perfect for positioning AS/RS, rail cars and gantry cranes.

Dust Measuring Devices

SICK is setting new standards in dust measurement with its rugged and low-maintenance measuring devices for detecting and monitoring dust concentrations. All dust measuring devices are easy to integrate into existing applications – and offer straightforward installation and commissioning along with user-friendly operation.

Fiber-optic Sensors & Fibers

When installation space is extremely limited or the objects to be detected are tiny, fibre-optic sensors are the ideal solution. If it is necessary for even higher requirements to be fulfilled, such as sensing range, temperature resistance, material durability or a flexible mounting process, the intelligent combination of sensors and fibre-optic cables can provide the perfect solution.

Fluid Sensors

Optimised control of process parameters is the main driver for increasing efficiency and reducing the input of valuable resources. SICK offers a wide range of solutions for measuring process variables for liquids, gases and bulk solids and protecting against overfill and dry run, whether it’s for pressure measurement, temperature measurement, level control or flow metering. SICK devices are rugged and easy to use. Innovative sensor technology enables accurate, universal measurement independent of material type.

Gas Analysers

SICK offers a broad range of gas analysers based on a variety of powerful measurement principles. With its in-situ and extractive measurement technology for equipping complete facilities, SICK can also provide solutions for a variety of systems and complex measurement tasks.

Analyser Solutions

SICK’s analyser solutions provide forward-thinking concepts for measuring tasks in the fields of emission and process measurement technology. Typical fields of application include emission and process measurements in power plants, waste incineration plants, cement plants, and the chemical industry.

Identification Solutions

Product traceability and anti-counterfeiting solutions require reliable automatic identification products. SICK offers the three most common industrial identification technologies: laser-based scanners for 1D codes, image-based 1D and 2D code readers, and RFID readers. Integrated interfaces enable the readers to communicate inside industrial networks and innovative functionality makes commissioning and operation easy.

Inertial Sensors

Knowing the position of objects is essential for process automation in mobile applications in particular. SICK offers a wide range of inertial sensors for this purpose. The product portfolio ranges from conventional static through dynamic inclination sensors which deliver accurate position information at all times, even in accelerated applications.

Integration Products

Integration products from SICK enable easy connection and networking of a wide variety of sensors at the field level as well as transmission of sensor data into the cloud. In keeping with Industry 4.0, the data is provided directly or in a preprocessed form in order to operate higher-level processes such as predictive maintenance, track and trace and quality control.

Line Guidance Sensors

Line guidance is a straightforward and cost-effective type of navigation for automated guided vehicles (AGVs) and mobile platforms. It functions through a sensor on the vehicle that detects and tracks a line on the ground, the sensor outputs the deviation to the vehicle control. Optical or magnetic line guidance sensors can be used depending on the requirements.

Magnetic Cylinder Sensors

Innovative Sick cylinder sensors features include ease of handling, the option of an analogue output, optimum switching characteristics, suitability for use in the food and beverage industry, support for the latest IO-Link technology, and universal mounting options with our comprehensive range of adapters, magnetic cylinder sensors from SICK are equipped for all installation locations and conditions.

Optoelectronic Protective Devices

Opto-electronic protective devices are the first choice in order to implement maximum productivity for machines and plants. Unlike fences and doors, they do not limit during handling or material transport and provide a better view in the machine room. The broad portfolio comprehensively meets the requirements of hazardous point protection, access protection, and hazardous area protection.

Registration Sensors

The variety of tasks in automated production processes today, such as in packaging and printing machines, require sensors with the highest performance standards. Typical applications are the detection of visible and non-visible marks, labels, and colours at high speeds as well as the detection of small parts and precise positioning. SICK offers a wide range of contrast, markless, colour, luminescence, fork, and array sensors to solve this wide spectrum of demanding tasks.

Industries

The SICK Group divides its business activities into factory automation, logistics automation, and process automation business fields.

Factory Automation

Electronics

Food and beverage

Handling and assembly technology

Health care manufacturing

Machine tools

Packaging

Print

Production logistics

Robotics

Rubber and plastics

Semiconductors

Solar

Stone, ceramic, glass

Textile

Wind energy

Wood

Logistics Automation

Airport

Building management

Building safety and security

Courier, express, parcel and postal

Cranes

Industrial Vehicles

Mobile automation

Port

Retail and warehousing

Storage and conveyor

Traffic

Process Automation

Building materials

Chemicals, petrochemicals, refineries

Maritime

Metal and steel

Mining

Oil and gas

Power

Waste and recycling

We are experienced distributors of product solutions across all industries, and we will be happy to help you to find the best options for your business. We have a large range of sensors and switchgear in stock in our Cork based store, and we offer flexible and comprehensive solutions. For expert advice and rapid supply of SICK products to meet your application needs, Contact Long Distributors today.

We are here to help

Feel Free To

Contact US

-

Address:

Unit 11, Northpoint Business Park, New Mallow Road,

Cork, T23 YR04 -

Email:

-

Phone: